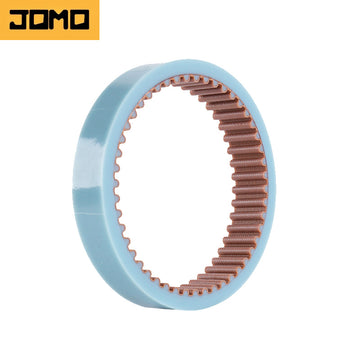

Carding belts usually consist of polyurethane body and steel cord, while custom materials available upon request. Special cords include aramid (kevlar).

Carding Machine Belts are potential replacement belts. Belts include AT10 and T10 see table below.

Applications include Rieter C 70/C70, C 60/C60, C 50/C51; LC 361/LC363, LC 333/LC333, LC 636/LC636; Trutzschler Truetzschler TC03, TC05, TC06, TC07, TC10, TC11, TC12, TC15, TC19i, TC 19i.

Carding Machine Belts are most commonly offered in widths of 25, 26mm, while custom sizes (lengths, widths and pitches) are available upon request.

Carding belts are timing belts with custom-made profiles and special cleats. Advantages of carding belts include high wear resistance, good quality and long life.

Carding is an essential process in the textile industry that involves separating, cleaning, and aligning fibers to create a continuous web or sliver. One of the key components in a carding machine is the carding machine belt. But what exactly is a carding machine belt and how does it work?

What is a carding machine belt?

A carding machine belt is a specialized belt that is used in carding machines to transfer fibers through the various stages of the carding process. It is made from high-quality materials such as rubber or synthetic fibers to ensure durability and longevity.

How does a carding machine belt work?

The carding machine belt is responsible for transferring the fibers from the feed section to the doffer section of the carding machine. It moves at a precise speed to ensure a consistent and uniform transfer of fibers. The belt's surface is designed to grip the fibers and prevent slippage, allowing for efficient and effective carding.

Key features of a carding machine belt

Carding machine belts have several key features that make them essential for the carding process:

- Durability: Carding machine belts are designed to withstand the rigorous demands of the carding process, including high speeds and constant tension.

- High friction: The belt's surface is engineered to provide high friction, ensuring a secure grip on the fibers and preventing slippage.

- Uniformity: The carding machine belt is manufactured to precise specifications, ensuring a consistent transfer of fibers and maintaining the quality of the carded material.

- Low maintenance: With proper care and maintenance, carding machine belts can have a long lifespan, reducing the need for frequent replacements.

Benefits of using a carding machine belt

Using a high-quality carding machine belt offers several benefits:

- Improved efficiency: The precise and consistent transfer of fibers facilitated by the carding machine belt leads to improved efficiency in the carding process.

- Enhanced fiber quality: The uniform transfer of fibers ensures that the carded material has a consistent quality, resulting in higher-quality end products.

- Reduced downtime: The durability and reliability of carding machine belts minimize downtime due to belt failures, allowing for uninterrupted production.

- Cost-effective: Investing in a high-quality carding machine belt can result in long-term cost savings by reducing the need for frequent belt replacements.

In conclusion, a carding machine belt is a crucial component in the carding process, facilitating the efficient and effective transfer of fibers. Its durability, high friction, and uniformity contribute to improved efficiency, enhanced fiber quality, and reduced downtime. By investing in a high-quality carding machine belt, textile manufacturers can optimize their carding operations and achieve higher-quality end products.