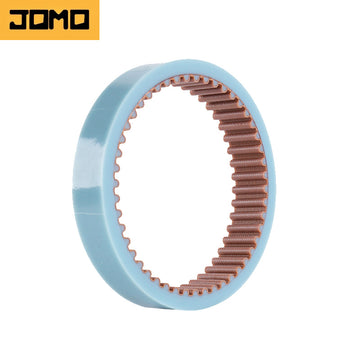

Carding machine belt T10-3040 cover belt button belt JOMO timing belt

by ZhangTina on Feb 06, 2024

A carding machine belt is an essential component in the textile industry, specifically in the process of carding fibers. Carding is the process of separating and aligning fibers to create a continuous web or sliver, which is then used to produce yarn or other textile products. The carding machine belt, also known as the T10-3040 cover belt or button belt, plays a crucial role in ensuring the smooth operation of the carding machine.

What is the purpose of a carding machine belt?

The primary purpose of a carding machine belt is to transfer power from the motor to the various components of the carding machine. It is responsible for driving the main cylinder, doffer, and other moving parts that are involved in the carding process. The belt's design and material are carefully chosen to provide optimal grip and durability, allowing for efficient power transmission.

How does a carding machine belt work?

The carding machine belt operates on the principle of friction. It is made of a high-quality material, such as rubber or polyurethane, which offers excellent grip and resistance to wear. The belt is looped around the pulleys of the carding machine, creating a continuous path for power transmission.

When the motor is activated, it rotates the main pulley, which, in turn, drives the belt. As the belt moves, it transfers the rotational force to the other pulleys connected to the various components of the carding machine. This rotational force enables the carding machine to perform its essential functions, such as feeding, carding, and doffing.

Why is the choice of belt important?

The choice of carding machine belt is crucial for the overall performance and efficiency of the carding process. A high-quality belt with the right specifications ensures smooth power transmission, reducing the risk of slippage or belt failure. It also minimizes downtime and maintenance requirements, allowing for uninterrupted production.

Additionally, the belt's material and design should be compatible with the specific requirements of the carding machine. Factors such as belt width, thickness, and surface texture can significantly impact the carding process's effectiveness. Therefore, it is essential to consult with industry experts or manufacturers to select the most suitable belt for a particular carding machine.

Conclusion

The carding machine belt, whether it is the T10-3040 cover belt, button belt, or JOMO timing belt, is a critical component in the textile industry. Its role in transferring power and enabling the smooth operation of carding machines cannot be overstated. By understanding the purpose and functioning of the carding machine belt, textile manufacturers can make informed decisions when selecting and maintaining this essential component.