- Turn off the power, remove the protective cover, and loosen the mounting bolts of the motor.

- Move the motor so that the timing belt has enough slack to remove it without prying it open, never pry the belt off.

- Remove the old timing belt and check for unusual wear. Excessive wear may indicate a problem with the design or maintenance of the transmission.

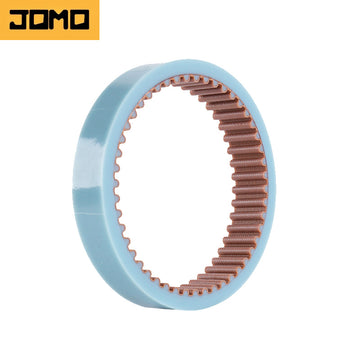

- Select the appropriate timing belt replacement.

- To clean the synchronous belt and the synchronous pulley, wipe the rag with a little non-volatile liquid. It is not advisable to soak it in detergent or use a cleaning brush to clean the belt. To remove oil and dirt, wipe it with sandpaper or use a sharp object. Scraping is obviously not advisable. Timing belts must be kept dry before installation and use.

- Check the timing pulley for cracks or wear, preferably with a professional measuring tool. If the wear is excessive, the timing pulley must be replaced.

- Check that the timing pulley is symmetrical in a straight line.

- Check the remaining transmission components such as bearings and bushings for symmetry, durability and lubrication.

- For multiple timing belt transmissions, all the timing belts must be replaced. If only one timing belt is replaced on a multiple timing belt transmission, the tension of the new timing belt may be appropriate, but all the old timing belts will be Without enough tension, the transmission may be loaded by this new belt alone, causing premature failure of the new timing belt.

- Tighten the center distance of the transmission device, turn the driving wheel a few times by hand, it is best to use a professional synchronous belt tension measuring instrument to check whether the tension is appropriate. If the tension is too strong, it will seriously affect the use of the timing belt. If the tension is insufficient, it will affect the transmission effect of the synchronous belt.

- Tighten motor mounting bolts to correct torque.

- Replace the protective cover.

- A trial run procedure is recommended. This procedure includes running the transmission, running it at full load and stopping, checking and adjusting the tension to the recommended value. Running the timing belt under full load allows the belt to fit into the pulley groove. It is good to run the belt 24 hours if possible, even overnight or during lunch breaks. Use the commissioning procedure to reduce the number of times you need to re-tension later. When the operation starts, check for abnormal vibration and listen carefully for abnormal noise. It is best to turn off the machine and check the condition of the bearings, motor or pulleys, if it feels too hot to the touch, the belt may be too tight, or the bearings may not be symmetrical, or may not be properly lubricated.

Causes of common problems with synchronous belt devices:

- envirnmental factor.

- Improper installation of timing belt and timing pulley.

- The transmission is poorly designed.

- Improperly maintained transmission.

- Transmission parts are defective.

- Improper storage or storage of belts.